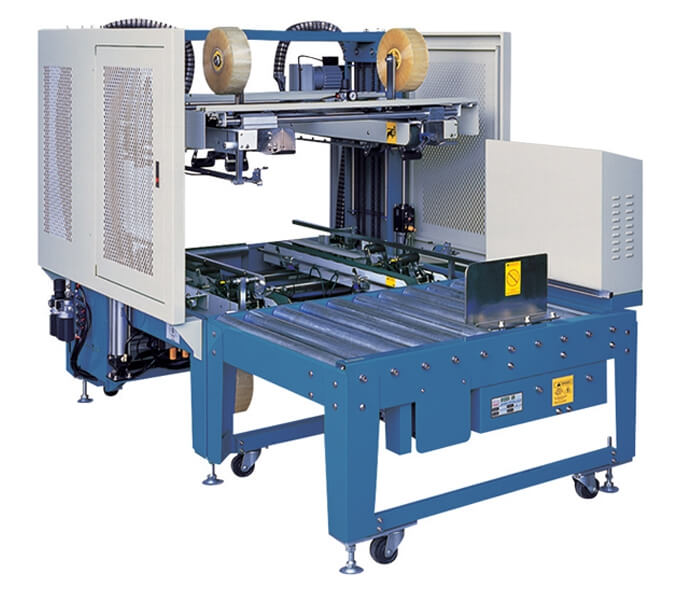

Random Automatic Four Edge Case Sealer

CHS-6702A

FEATURES

FEATURES

- Carton dragging by Top & Bottom belts with independent motors

- Automatic adjustment of carton width and height. Continuously produce random cartons.

- Have both of regular mode (random sizes) and memory mode (uniform size)

- Carton sealing : seal the upper and lower 4 edges for strengthen

- Suitable for :

(1) Users with export demand. (Improve box support)

(2) production line is processed by robot arm. (Reinforced box) - PLC controlled to alter the program easily

- Infeed push-carton conveyor, the carton will be pushed off 90 degrees into the edge sealer where it completes the "H" seal top and bottom.

- Stainless roller table for carton movement

- The tape head is developed and produce by CHA PACK, the length of tape that can be placed up to 900m. (260mm diameter)

- Dual telescoping mast with cushion. Adjust the unevenness of the carton.

- Machine with mobile casters and feed, easy to move

- 7" HMI can be available as an option. To provides convenient for technician to operate and flexible adjustment of machine’s parameters. To reduce the time for error elimination and accelerate the maintenance efficiency

- Bespoke designs of carton edge sealer for lower height of carton from H110mm

- Carton edge sealer is designed to meet the needs of random in-line carton closure applications

- Machine can be available with other equipments, e.g: 1. Labeling mc. 2. Weighing mc. 3.Inkjet Printers

- Parts are manufactured with mold.- Stable quality, Short lead time

- Machines are designed and produced by ourselves. Rugged design, low maintenance rate

- 90% self-production rate, 100% Made in Taiwan.

SPECIFICATIONS

SPECIFICATIONS

| Model | CHS-6702A | |

| Function | Top & Bottom belt driven | |

| Power Supply | 3 phase, 220V/380V/415V | |

| Tape Width | 2“ or 3" | |

| 2" & 3" Tape Sealing size | L280-630mm, W250-600mm, H225-600mm | |

| Tape overlap | L60±5 (mm) standard | |

| Working table height | 570-770mm | |

| Conveyor Speed | 20 M/min | |

| Capacity | 4~5 cases/mins. ( Random sizes ) 10~12 cases/mins. ( Uniform size ) ( Data is for carton length=300mm) **Depending on box size and operator efficiency.** |

|

| Machine dimension | L2100 x W1460 x H1500mm | |

| Air compressor | 6kg/cm² | |

| ※CHA Pack reserves the right to modify specification for quality development. | ||

OPTIONS