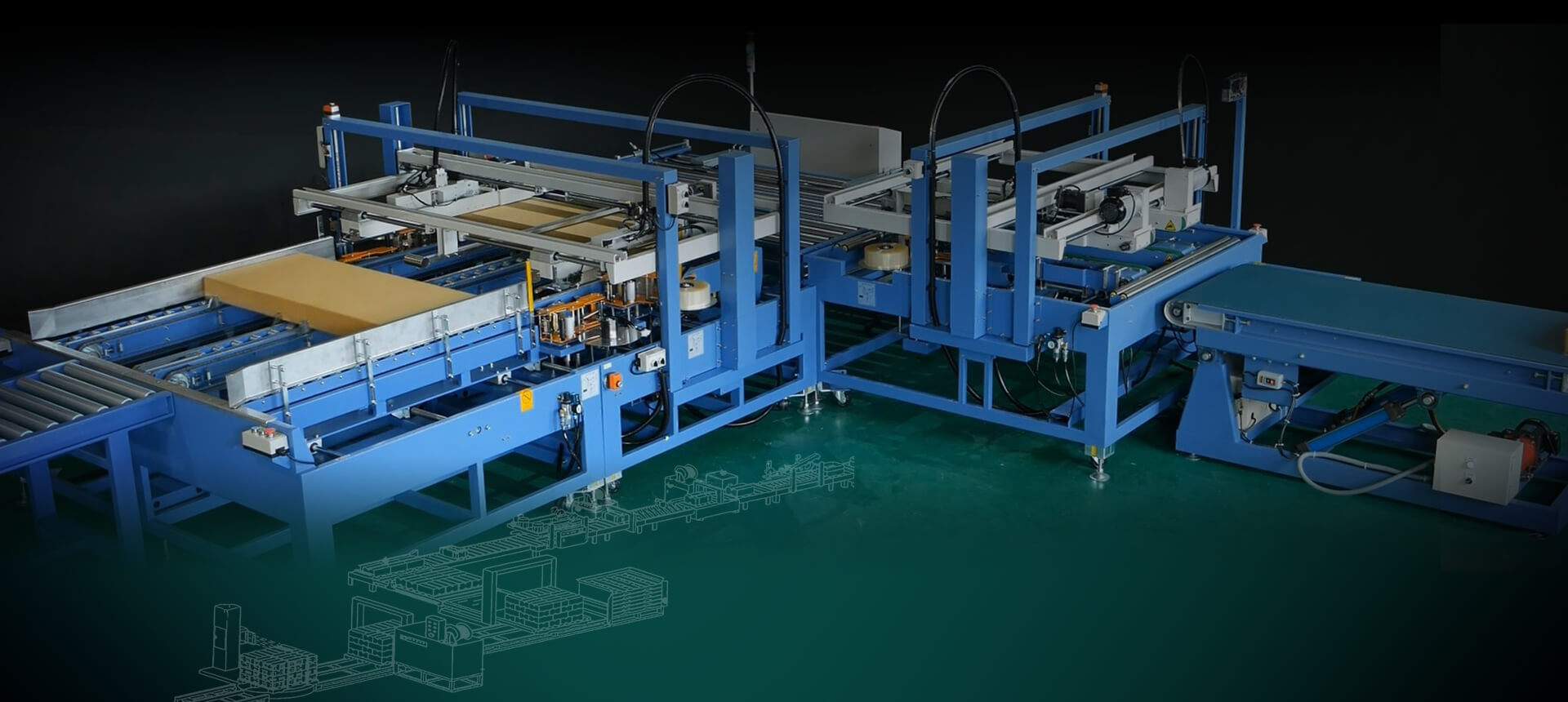

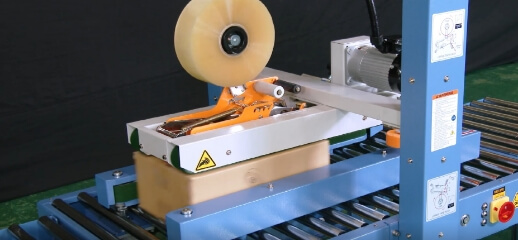

YOUR PACKAGING NEEDS. WE OFFER CREATIVE SOLUTIONS SINCE 1986

In the past 30 years of industry experience, CHAN PACK was created to manufacturer end-of-line packaging equipment to service the needs of different industrial customers. Lear more about who we are and our dedication to serving our customers here.